An important aspect to increase the longevity of optical sorters is providing ultraclean compressed air that is free of moisture, oil emulsion fluids and dust.

Why?

Because the internal valve mechanisms could fail, causing the valves to remain in the open or closed position.

What problems does this cause?

Reduced performance An 80-inch-wide, single-eject optical sorter normally uses 80 valves. If just four valves are not functional, that means 5 percent of the machine width is not performing at all, causing recovery of the targeted commodities to decline. Part replacement costs These valves cost in region of £60-£80 each to replace Reduced productivity When the performance of your optical sorting machine/s is compromised, the overall output and productivity of the site is directly impacted.

What is the solution?

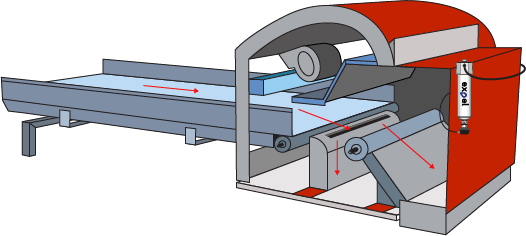

The solution is the Expel compressed air filter Expel is a 3-in-1 solution: Expel removes liquid water, oil emulsion fluids and solid particulates all from a single unit down to 1 micron. It is not uncommon for Expel to replace the need for several compressed air filters including bulk water separators, coalescing filter and 1-micron particulate filters. Traditional compressed air filters use disposable internal elements: These elements become less effective with use. This is exactly why we designed Expel because your equipment is reliant on clean and dry compressed air. We identified the need for a far superior solution that never reduces in performance and its reliability is never compromised. These features make Expel the perfect source of protection for optical sorting machines. BACK