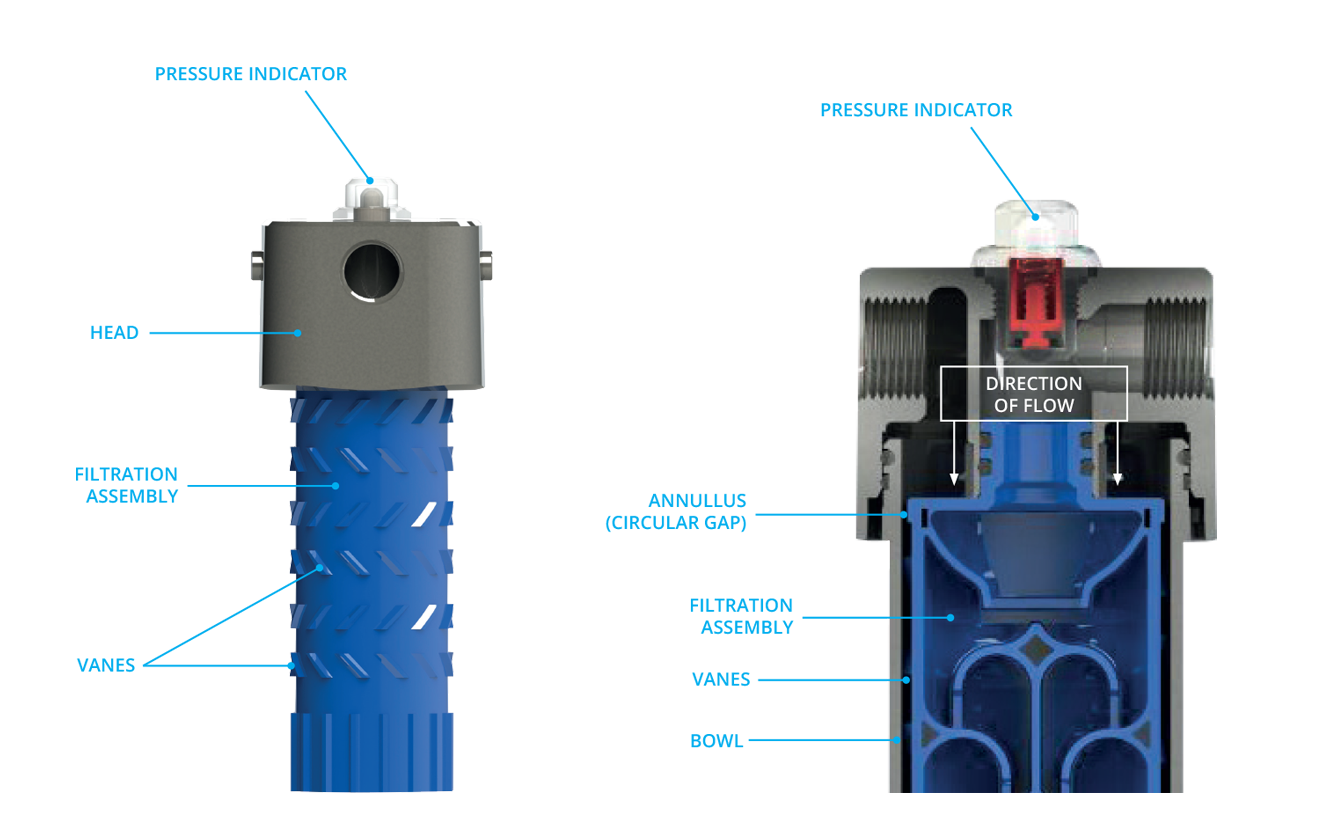

How EXPEL works

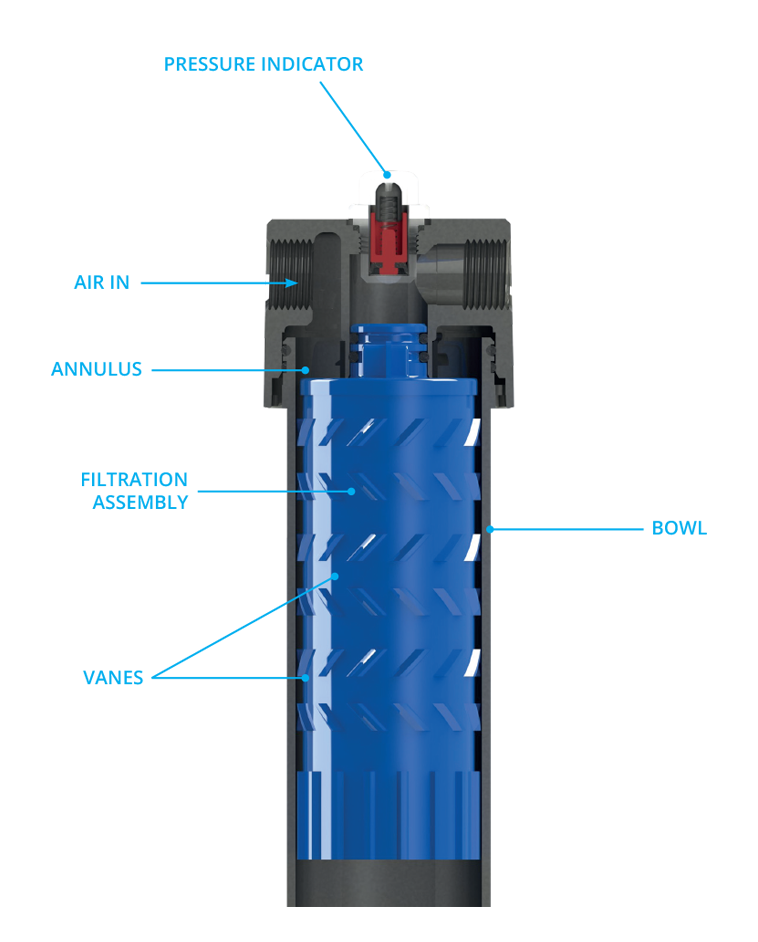

1. The Manifold (Head)

The compressed air enters the Head of the Expel unit through the inlet port and is directed downwards between the Bowl and the Filtration Assembly.

A quick release mechanism alloys the Head and Bowl to be easily opened for cleaning while a Pressure Indicator warns if the compressed air filtration unit is under pressure.

2. The Filter (Filtration Assembly)

As the compressed air moves downwards the zig-zag directed Angled Vanes direct the air in opposing directions.

3. The Filter (Filtration Assembly)

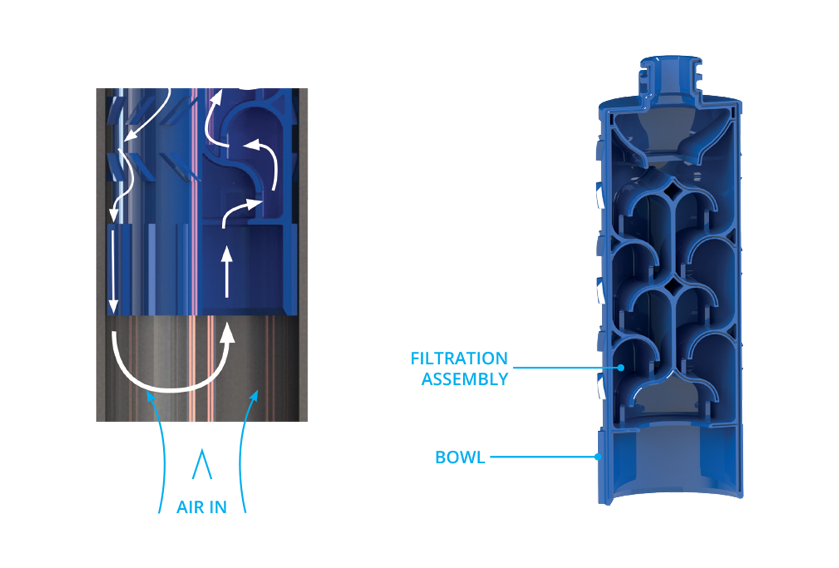

Circulating moisture (oil and water) and particulates are deposited through gravity and air speed at the base of the of the Shell bowl.

The water droplets, oil and particles are forced to the base of the Bowl and exit through the drain port while the dry air continues upwards into the Umbrella Assembly or Vertical Unitary Body (VUB).

95% of separation (Water, Oil and Solids) takes place at this stage of the process.

4. The Filter (Filtration Assembly – UVB)

The Umbrella Assembly (UVB – Unitary Vertical Bodies) consists of TWO vertical parts that are sonically fused together.

Each half of the UVB consists of component parts which, when fused together to create multiple, over-lapping umbrella-shaped chambers.

As the air is forced upwards any remaining Water, Oil and Particles are coalesced together forming droplets that fall through gravitation force downwards and out through the base of the bowl.

The UVB is easily removed and cleaned as part of periodic maintenance should it be necessary.

Up to 5% of Liquid and Particulate Separation (Water, Oil and Particulates) takes place at this stage of the process.

Brands we have sold to...