PROTECTING YOUR CONTROL VALVES AGAINST MOISTURE CAN SAVE YOUR SITE THOUSANDS OF POUNDS, REDUCE MAINTENANCE AND REDUCE DOWNTIME!

Just a few droplets of moisture in compressed air lines can damage the positioners on control valves. When this problem occurs, the only way to rectify the damage is to completely replace the positioner which costs in the region of £1,000 to replace each time!

Traditional compressed air filters can NEVER guarantee that moisture will not reach your control valves. This is because they contain internal elements which become less and less effective with use.

Furthermore, your dryer could fail, then you’re almost guaranteed to have moisture cause damage to the positioner on your control valve.

SO, HOW CAN YOU MAKE SURE THAT LIQUID WATER NEVER REACHES YOUR CONTROL VALVES?

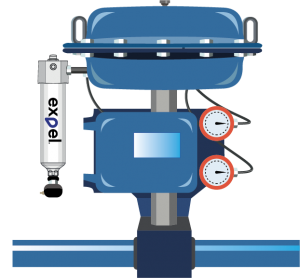

Installing Expel at point of use ensures that ALL liquid water, oil emulsion fluids and solid particulates down to 1 micron are CONTINUALLY removed right before the compressed air will be used.

Expel is not like ANY other compressed air filter currently on the market because it does not require any replacement filter elements. Therefore, there is NEVER any drop in performance, and it always operates at 99.999% efficiency!