Tyre Industry Case Study: Lodge Tyres, Stafford Branch

“Expel has had a big impact, it’s greatly reduced the amount of water and reduced the maintenance costs on the fitting machines, and we are no longer having those problems! I’d recommend Expel to anyone who has fitting machines, MOT bays, or anywhere you have got compressed air lines”.

Trevor Standeven – General Manager – Lodge Tyres

About the customer

Project Background

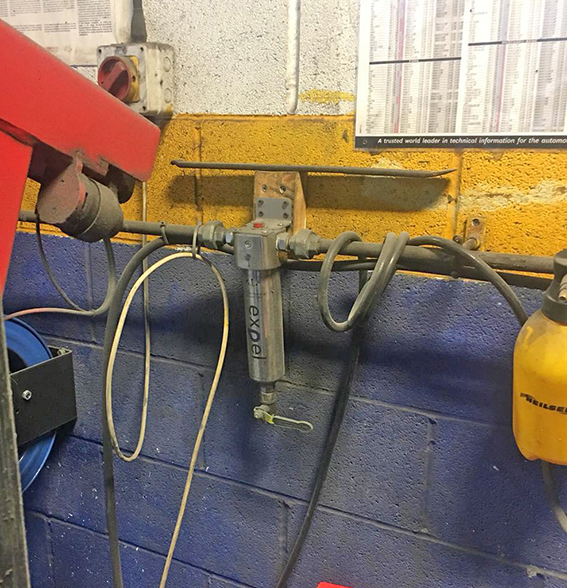

General Manager of the Lodge Group Trevor Standeven, was becoming increasingly concerned about the volume of water that was entering the compressed air lines and knew he needed to take action because of the extensive damage to the following equipment that it was causing:

- Water in the airlines leading to the four postal air lifters was becoming increasingly problematic for the Stafford Branch, especially in the winter months because the water would freeze in the compressed air lines which disabled the ramp from operating properly.

- Fitting Machines were another chief concern to Trevor and his workforce because seals in the bead breakers were constantly breaking down, leading to large and avoidable maintenance costs and equipment downtime.

Why did Lodge Tyres chose Expel?

Being a customer focussed company, Trevor understandably did not want to waste unnecessary time dealing with equipment downtime and paying endless avoidable maintenance costs when they could be channelling these efforts into providing a superior level of customer service. Expel is the best compressed air filter to fulfil this goal due to the fact that its efficiency remains consistent at 99.999% and does not contain any materials that need replacing.

THE RESULTS

Reduces Downtime

Reduces Costs

Reduces Maintenance